In the world of chocolate manufacturing, the efficiency and quality of production can often hinge on the technology used in transferring chocolate from one point to another. This is where chocolate transfer pumps come into play, serving as a critical component in the chocolate production process. Recent innovations in pump technology are transforming the way chocolate is handled, ensuring that this beloved delicacy maintains its quality while being transported efficiently. This article will explore the latest advancements in chocolate pump design and how they are reshaping the industry.

Understanding Chocolate Transfer Pumps

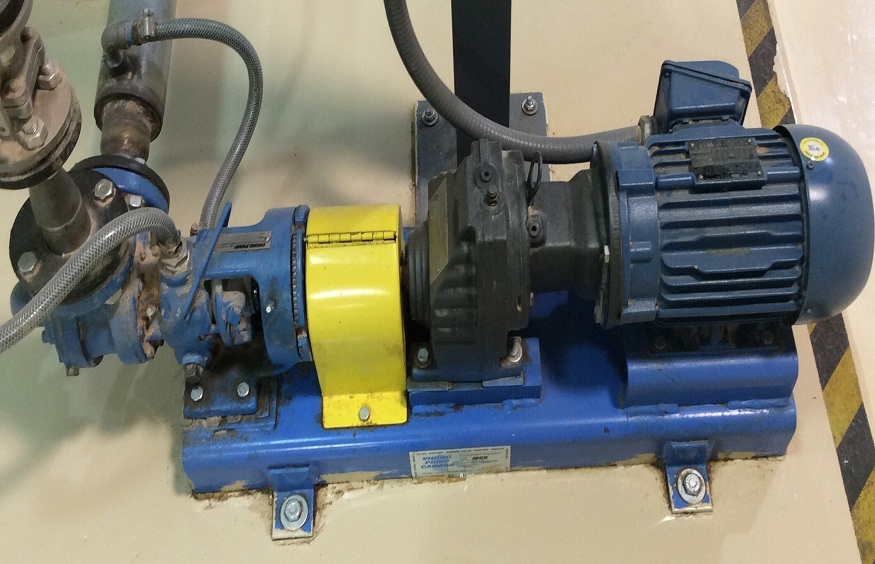

Chocolate transfer pumps are specially designed to move liquid chocolate through various stages of production. Unlike traditional pumps, these systems are engineered to handle the unique viscosity and consistency of chocolate, ensuring a smooth flow without compromising the quality of the product. The design of these pumps can significantly influence the overall efficiency of the manufacturing process.

The Importance of Pump Design

The design of chocolate transfer pumps is vital for several reasons:

- Preserving Chocolate Quality: Chocolate is a sensitive product that can easily be damaged by excessive shear, heat, or contamination. High-quality pumps minimize these risks by providing a gentle transfer process that maintains the chocolate’s texture and flavor.

- Efficiency in Production: In a competitive market, manufacturers must optimize their production lines to reduce waste and downtime. Efficient pumping systems contribute to a seamless operation, ensuring that production flows smoothly from one stage to the next.

- Flexibility in Application: Chocolate transfer pumps are often used in a variety of applications, from transferring molten chocolate to filling molds. A versatile pump design can adapt to different production requirements, making it an invaluable asset in any chocolate manufacturing facility.

Recent Innovations in Chocolate Pump Technology

As the chocolate industry continues to evolve, so too do the technologies that support it. Several recent advancements in chocolate transfer pump design are worth noting.

1. Enhanced Flow Control Systems

Modern chocolate pumps are increasingly equipped with sophisticated flow control systems that allow for precise management of chocolate transfer rates. These systems can be adjusted on the fly, enabling manufacturers to respond to changing production needs without interrupting the flow of operations. This flexibility not only improves efficiency but also reduces the risk of overflows or bottlenecks in the production line.

2. Improved Materials and Construction

The materials used in constructing chocolate pumps are critical to their performance. Recent innovations have seen the introduction of new materials that offer enhanced resistance to corrosion and wear, ensuring that pumps can withstand the rigors of continuous operation. Additionally, advancements in surface coatings help to prevent chocolate from sticking to the pump, further enhancing efficiency and reducing cleanup times.

3. Compact and Modular Designs

Space is often at a premium in manufacturing facilities, prompting the need for compact and modular pump designs. Innovations in this area allow for the creation of smaller pumps that still deliver high performance. These modular designs can be easily integrated into existing production lines, making them an attractive option for manufacturers looking to upgrade their systems without extensive renovations.

4. Energy-Efficient Solutions

In today’s environmentally conscious world, energy efficiency is a priority for many manufacturers. Recent developments in pump technology have focused on reducing energy consumption while maintaining optimal performance. By utilizing advanced motor designs and energy recovery systems, these pumps can significantly lower operational costs while contributing to a more sustainable production process.

The Role of Flow Dividers in Chocolate Transfer

Flow dividers are crucial components that can enhance the functionality of chocolate transfer pumps. These devices are designed to split the flow of chocolate into multiple streams, allowing for simultaneous transfers to various destinations. This capability is particularly valuable in large-scale operations where multiple production lines are running concurrently.

Benefits of Using Flow Dividers

- Increased Efficiency: By allowing for the simultaneous transfer of chocolate to multiple locations, flow dividers help streamline production processes, reducing waiting times and improving overall throughput.

- Consistent Quality: Flow dividers ensure that each stream of chocolate is evenly distributed, preventing variations in quality between different batches. This consistency is essential for maintaining brand integrity and customer satisfaction.

- Reduced Risk of Contamination: By keeping the flow of chocolate separate, flow dividers can minimize the risk of contamination during transfers, ensuring that the final product remains pure and safe for consumption.

Future Trends in Chocolate Pump Technology

As the chocolate industry continues to grow, several trends are likely to shape the future of chocolate transfer pump technology:

1. Automation and Smart Technology

The integration of automation and smart technology into chocolate manufacturing is gaining traction. Future chocolate pumps may be equipped with advanced sensors and monitoring systems that allow for real-time data collection and analysis. This information can be used to optimize performance, predict maintenance needs, and enhance overall production efficiency.

2. Sustainability Initiatives

Sustainability is becoming an increasingly important focus for manufacturers across all industries, including chocolate production. Future innovations may include designs that prioritize the use of recyclable materials, as well as pumps that minimize energy consumption and waste during operation. By aligning with sustainability goals, manufacturers can appeal to eco-conscious consumers and contribute to a healthier planet.

3. Enhanced Customization Options

As consumer preferences shift, the demand for customized chocolate products is on the rise. Future chocolate pumps may offer greater flexibility in terms of design and functionality, allowing manufacturers to create unique products that cater to specific market trends. This adaptability will be key in maintaining competitiveness in an ever-evolving industry.

Conclusion

Innovations in chocolate pump technology are playing a crucial role in enhancing the efficiency and quality of chocolate production. From improved materials and compact designs to the integration of flow dividers, these advancements are reshaping the chocolate manufacturing landscape. As the industry continues to evolve, the focus on automation, sustainability, and customization will likely drive further innovations, ensuring that chocolate remains a beloved treat enjoyed by consumers worldwide. By embracing these cutting-edge technologies, manufacturers can not only improve their operations but also contribute to a more sustainable future in the chocolate industry.